1.ApplicationNumber: US-9055036-A

1.PublishNumber: US-2086514-A

2.Date Publish: 19370706

3.Inventor: SAUNDERS SEYMOUR G.

MORRISON HARRY

4.Inventor Harmonized: SAUNDERS SEYMOUR G()

HARRY MORRISON()

5.Country: US

6.Claims:

7.Description:

(en)July 6, 193 7.

S. G. SAUNDERS Er AL COATING MATERIAL RECOVERY PROCESS Filed July 14, 1936 2 Sheets-Sheet l 3 f QSEYM OUR a. SAUNBEHE AND HARRY MORRlON.

GttornegS y 1937- s. G. SAUNDERS ET AL 2,086,514

COATING MATERIAL: RECOVERY PROCESS Filed July 14, 1936 2 Sheets-Sheet 2 lhwemor \SEYM OUR G. 6A UNDERS AND HARRY MORRIQSON.

Gttornegs as to return them to a condition suitable for reprovide an improved method of this character Patented July 6, 1937 COATING MATERIAL RECOVERY PROCESS Seymour G. Saunders, Birmingham, and Harry Morrison, Detroit, Mich, assignors to Chrysler Corporation, Highland Park, Mich, a. corporation of Delaware Application July Serial No. 90,559

a precipitating agent of this character in the presence of excess quantities of which the solids or non-volatile constituents of the surface coating material are insoluble in the solvent of the latter and in which such solvent is either soluble or mixable.

Still further objects of the invention are to provide in the force. draft air passage of a spray booth, curtains of liquid material for washing out the solid constituents of the air passing from the booth; and to provide curtains of liquid material which serve as precipitating agent for the particular type of solids of the coating material being sprayed in the booth.

Another object of the invention is to provide a coating material recovery and reconditioning process and apparatus by which the recovered products can be used in compounding materials of the same or different character from which they were derived or in manufacturing articles of diverse compositions.

Additional objects of the invention are to provide an improved exhaust system for spray coating booths which is particularly adapted to facilitate the removal of solid coating material constituents from the air exhausted therefrom; to provide means in the exhaust system of a spray chamber for reversing the course of the flow of the air passing therefrom and substantially simultaneously subjecting the air to a spray while its course of travel is being reversed; to provide an outlet for the spray liquid and solid material collected thereby which is spaced from the normal path of the main portion of the air being exhausted from the spray boating chamber; and to provide a sump for collecting the sprayed washing liquids and solid matter collected thereby.

Another object of the invention is to provide a plurality of separate sumps for receiving liquid washing mediums carrying respectively differentlycolored coating material constituents; to provide a plurality of outlets for the washing medium, each of which is adapted to communicate with one of the sumps respectively; and to provide selectively controllable means which are adapted to be so positioned as to direct the differently colored solid coating material constituents to their respective sumps.

In general, the ingredients of surface coating materials can be broadly classified as volatile and non-volatile solvents, non-volatile vehicle, pigment and coloring matter, and driers. In the manufacture of such coating materials a large part of the time, labor and machinery cost in- 13 Claims.

This invention relates to an improved method and apparatus for recovering the non-volatile ingredients of sprayed surface coating materials, commonly called solids, from the atmosphere of the space in which they are applied, and is a continuation in part of our applications, Serial No. 19,794, filed May 4, 1935, and Serial No. 45,962, filed October 21, 1935.

More particularly, the invention pertains to the recovery of solids of paint, lacquer, natural enamel, synthetic enamels and the like.

The term solids, as used herein and as conventionally employed in the surface coating art refers to those portions of surface coating material which remain, either in their initial or chemically altered form, in a normally set deposit of such coating materials, including the non-volatile vehicle and pigment.

One of the main objects of the invention is to by which the recovered products are retained in such condition that they can be readily dissolved in, or dissociated throughout a solvent with which they had previously been associated, so

use in an identical manner.

Another object of the invention is to provide a recovery method of this character by which substantially all the solids of the coating material of the air withdrawn from the vicinity of the application of coating materials is precipitated and collected.

Another object of the invention is to provide a suitable precipitating agent for the particular solids of the coating material to be recovered, which both separates the coating material from the air and precipitates the solids thereof from their solvent, while leaving the pigment of the coating material thoroughly dispersed throughout the vehicle thereof, and in condition to be re-incorporated in a solvent without requiring regrinding.

Another object of the invention is to provide precipitating agents of this character which lubricate the recovered material or the surfaces with which the recovered material contacts or which otherwise render the recovered material non-adhesive to such surfaces.

A further object of the invention is to provide an improved method and apparatus for recovering the solids of sprayed coating materials which prevents oxidation thereof and conversion of the recovered product to an insoluble, or other state not suited for re-use in coating operations.

Another object of the invention is to provide volves the grinding of the pigment into a finely divided and dispersed state in the non-volatile vehicle. Any recovery process during which this dispersion of pigment and npn-volatile vehicle is destroyed, naturally falls far short of saving these cost factors. In the present process the nonvolatile vehicle is recovered with the pigment dispersed therein substantially as thoroughly as it was in the initial surface coating material. Briefly, this is accomplished by precipitating the solids in the form of a sludge with the pigment thoroughly dispersed in the vehicle by treating excess sprayed coating material with a liquid, in

the presence of excess quantities of which the solids are insoluble and immiscible in the solvent.

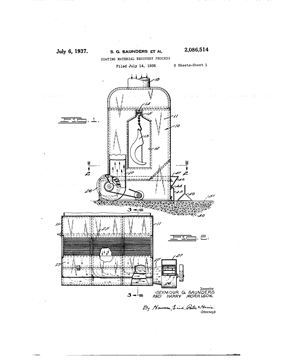

An illustrative embodiment of the invention is shown in the accompanying drawings, in which:

Fig. 1 is an end elevational view of a spraying booth equipped with solid coating material constituent recovering apparatus embodying the invention.

Fig. 2 is a horizontal sectional view taken on the line 2-2 of Fig. 1.

Fig. 3 is a vertical sectional view taken on the line 3-3 of Fig. 2.

Fig. 4 is a fragmentary sectional view taken on the lined-4 of Fig. 3.

Fig. 5 is a fragmentary illustrative horizontal sectional view taken on the line 5-5 of Fig. 3 and in addition showing a precipitating agent recirculating system.

In the drawings is shown one form of spray chamber, generally designated by the numeral Ill, with which the solid matter recovery apparatus may be used. The spraying chamber includes a casing having end walls ll provided with registering openings l2 for accommodating the passage of articles l3 through the interior thereof. The articles are preferably conveyed through the spray chamber III by a conveyor which includes a rail l4 extending longitudinally of the chamber l0 and located at the upper extremities of the openings l2 thereof. The rail I4 is adapted to movably support a plurality of carriers l5 which are preferably attached to a continuous conveyor chain (not shown). The spray chamber III has a roof H5 in which is formed an air inlet opening 11 that communicates with a conduit i8 leading from an external or internal source of air. Disposed immediately below the air inlet I1 is an inverted frusto-conical deflector [9 having vanes 20 so constructed and arranged as to distribute the air current entering the inlet ll throughout substantially all portions of the interior of the chamber l0. Provided at the lower longitudinal extremity of the spray chamber Ill on the side thereof opposite from the location at which the coating material is discharged upon the articles by a spray gun 2|, or other suitable means, is an inclined baifie 22 which slopes downwardly and inwardly toward the central portion of the floor 23 of the chamber. An air outlet opening 24 is provided in the floor 23 adjacent the lower extremity of the bailie 22 for permitting the escape of the air admitted through the inlet 21. A grill 25 is disposed. in the outl t opening 24 for the purpose of preventing the passage of articles or spray gun parts or other devices which may accidentally be dropped in the spraying chamber.

The air current is drawn through the inlet opening I! and through the interior of the spraying chamber H] by a blower 26 located externally of the spraying chamber and having a discharge conduit 21 which preferably leads to the atmosphere. The blower 26 includes an inlet conduit 21' which communicates with an air passage 28 disposed below the spraying chamber l0 and extending longitudinally thereof. The passage 28 leads from the outlet at of the spraying chamber In and is provided at its inlet end with curvilinear bafiles 29 and 30 which direct the air passing through the outlet 28 rightwardly as viewed in Fig. 3 toward the right extremity of the passage 23; The lowermost baflle 29 extends rightwardly further than the baflle 30 but it terminates in spaced relation to the right extremity of the passage 28 so as to permit the air current to be reversed in direction of flow by a curvilinear bafile 3! located at the upper right extremity of the air passage, as viewed in Fig. 3. The air current flows around the right extremity of the lowermost baflle 29 and then continues in a leftward course toward the blower 26. An eliminator 32 is provided adjacent the outlet of the air passage 28 for removing any liquid such as spray coating material, or the precipitating agent introduced into the air current in the manner hereinafter set forth, before the air enters the blower 26 and discharge pipe 21.

The spray chamber l0 and the air passage 28 are provided with means for subjecting the air current circulated through the system to the action of an agent for precipitating the solids oi the excess sprayed coating material which is carried by the air current. The precipitating agent I preferably comprises liquid which not only washes or otherwise removes the sprayed coating material from the air current but which also precipitates the solid constituent thereof from the solvent in which they are incorporated.

In the form of the invention illustrated, a discharge pipe 33 having a plurality of relatively small outlet orifices or other spray forming means, extends longitudinally of the spray chamber I 0 and is located adjacent the back wall 34 thereof as illustrated in Fig. 3. The orifices, or spray devices of the discharge pipe 33 are so constructed and arranged as to direct the precipitating agent upon the internal surface of the rear wall 34 and to cause the liquid to flow downwardly thereon substantially in the form of a sheet or curtain. The liquid precipitating agent is then directed inwardly toward the outlet opening 24 by the inclined baflie 22 and ultimately flows through the outlet openings 24 along with the air current. That portion of the excess sprayed coating material which impinges upon the sheet or curtain of liquid precipitating agent discharged by the pipe 33 is removed from the air current and the solids thereof are precipitated from their solvent. Any portion of the air ladened with spray coating material which is not subjected to the washing and precipitated action of the agent discharged by the pipe 33 is thoroughly treated with precipitating agent by a pair of spray devices 35 and 36 located in the left end portion of the air passage 28. The uppermost spray device 35 includes a plurality of outlet orifices or spray nozzles which discharge the precipitating agent in the direction of travel of the air current. flowing through the section of the passage 28 above the baille 29, and the spray device 26 likewise includes a plurality of orifices or discharge nozzies which spray precipitating agent in a direction opposite to the direction of flow of the air current through that portion of the air passage 26 located below the baiile 29. In this manner the precipitating agent is applied to the air current of the passage 28 at the location therein where the air current is reversed in the direction of movement.

Provided in the lower wall of the air passage 28 is an outlet 31 for accommodating the flow of the precipitating agent and solids of the spray coating material therefrom. The outlet 31 communicates with an elongated passageway or conduit 38 having a plurality of longitudinally adjacent discharge outlets 39, each of which communicates with a separate sump 40, as illustrated in Fig. 5. In the illustration shown there are provided three outlet openings 39 and associated sumps 40, each of which is intended to receive precipitating agent ladened with a differently colored solid coating material constituent. Although only three sumps are illustrated in the drawings, there may be provided as many thereof asarerequired to separate and segregate the,

solids of differently colored coating materials that are applied in the spray chamber l0.

Each outlet 39 of the conduit 38 is provided with a valve member or other adjustable closure,

illustrated in the drawings as a hinged damper 4|. Each closure 4! is provided with control mechanism, illustrated in Fig. 3, which includes a ball crank lever 42 pivotally mounted on the back wall 43 of the air passage 28 and having a lower arm 44 pivotally connected with the closure 4| by a link 45. The bell crank lever 42 also includes an upper arm 46 which is operatively connected with a control rod 41 extending transversely of the spray booth and having an operating handle 4I' located within convenient reach of the operator and preferably disposed on that side of the spray booth at which the operator stands. The closures 4| may be selectively controlled by the operator to correspond with the particular color of surface coating material being applied in the spray chamber In so as to deliver substantially all of the precipitating agent carrying any colored surface coating material to its proper sump. When it is not desired to separate the differently colored coating materials, they may all be collected in one sump and the resulting recovered product may be used in conjunction with predominating pigments, such as black, or for protective purposes where appearance is immaterial.

The recovered solids from many sprayed surface coating materials will sink to the bottom of the sump in the form of a sludge when a proper precipitating agent is employed and in this case the solids may be conveniently removed from the sump 40 by the aid of a liquid pervious screen 48 which is preferably disposed at the bottom of each sump 40. Cables 49 are attached to the screen 48 and preferably extended over a pulley 53 so as to enable convenient vertical movement of the screen 48- from the interior of its sump when it is desired to displace the precipitated solids therefrom.

With the use of certain precipitating agents for removing the solids of some sprayed surface coating materials, it is found that the solids float on the top of the liquid, in the form of a scum or sludge, in the sump 40 and may be conveniently removed therefrom by scraping the floating scum-like substance so formed into a trough from which it may be conveniently removed for further operation in accordance with the recovery process.

The precipitated solids obtained in either of the foregoing ways include the non-volatile vehicle dispersed coloring matter or pigment and substantially all other ingredients which comprise the solids of surface coating materials. In this recovery product, the pigment is thoroughly dispersed in the non-volatile vehicle in substantially that condition produced by the original grinding operations employed' in the initial manufacture of the coating material. These recovered products are then separated from the precipitating agent, preferably by initially removing the main portion of the latter in a press and then allowing the material to dry. For some purposes more complete removal of the precipitating agent is desirable and in this event the precipitating agent is preferably washed out or extracted, as hereinafter more clearly set forth, with a suitable solvent therefor which will not dissolve or otherwise seriously disturb the condition of the recovered solids. The thus reconditioned recovered material may then be dissolved in a solvent of the same character as that from which it had previously been separated in order to produce surface coating material which is otherwise wasted.

Various precipitating agents may be used in the foregoing process depending mainly upon the particular nature of the coating material from which the solids are to be recovered. In recovering the solids from cellulose lacquers it is preferable to use water as a precipitating agent, while in recovering the solids from paint and enamels of the synthetic and natural type, the use of a mineral oil as the precipitating agent is particularly advantageous. While a vast number of mineral oils of different distillation temperatures may be employed for this purpose, it is preferable to use those which do not readily evaporate such as mineral oils having a distillation temperature not lower than that of kerosene. Paraifin oil and mineral oils having distillation temperatures be- I tween those of paraffin oil, and kerosene operate successfully in recovering solids from sprayed paint, lacquer and enamels as well as from glyptol resin base synthetic coating materials.

The solids of substantially all spraying types of coating materials .can be economically and commercially recovered by using in the foregoing process a precipitating agent comprising an emulsion of soluble oil in water. This precipitating liquid is particularly suitable for the recovery of natural resin and oil base coating materials and synthetic resin base coating materials such as alkyd, resin base varnishes, enamels and lacquers, and the like. It may be used in the recovery of nitrocellulose lacquers, but, for the purpose of economy, water is recommended for recovering this type of coating material. The oil content effectively prevents the deposited precipitate from adhering to the surfaces of the enclosure in which the process is conducted and through which such materials are conveyed.

Water miscible oils, commonly called soluble oils, of variouscharacters may be used in our improved recovery process. These oils are readily miscible with water and maintain a stable emulsion. When a soluble oil base derived by treatment of mineral oil, for example, with naphthenic acid is used, it is preferable to neutralize the free acid content with a suitable alkali such as potassium hydroxide or sodium hydroxide. Any soluble oil base employed should be either neutral or only slightly acid for the presence of a comparatively strong alkaline condition results in saponification, and hence waste of the resin content of the solids. Other alkali may be used, but the introduction with the alkali of solvents for the resins of the solids should be carefully guarded against.

Although proportions of soluble 011 base and large excess of washing solvent.

water of the precipitating medium may vary within wide limits, for purposes of economy, flowability and general convenience of operation, emulsions of water and oil, respectively, varying from parts of water to 1 part of soluble oil base; to 30 parts of water to one part of soluble oil base are preferred.

Irrespectiveof the saving resulting from the recovery of excess sprayed coating materials, the use of precipitating agents in the foregoing manner and in which the solids of the coating materialare not soluble or rendered gummy, is of substantial value. The elimination of the nuisance problems involved in the discharging of air fromspray booths into the atmosphere in densely inhabited regions, as well as the saving in cleaning of the apparatus and removing therefrom, deposited solid and semi-solid accumulations represent a material saving in spray booth operation even though no attempt is made to reuse the recovered coating materials.

The precipitating medium may be withdrawn periodically from the sump 40 through conduits 52, each having a valve 53 therein, and discharged into a receptacle 54. The receptacle 54 is preferably provided with a filtering partition 55 through which the liquid precipitating agent must pass before being returned to the pipe 33 and spray devices 35 and 36 through an outlet pipe 56 having a branch pipe 51 communicating with the discharge pipe 33, and a branch pipe 58 communicating with the spray devices 35 and 35. The branch pipes 51 and 58 are preferably provided with valves 59 and 60, respectively, for individually controlling the flow of precipitating liquids to the pipe 33 and spray devices 35 and 36, respectively. The precipitating liquid may be recirculated in the foregoing manner and repeatedly redischarged in the spraying cham-' her It) under the pressure of a pump 6| included in the outlet conduit 56 or otherwise suitably located.

Complete removal of any precipitating agent which remains in the recovered product can be accomplished by washing the material with a suitable solvent for the particular precipitating agent used in the recovery process and in which the solids are insoluble. When mineral oil is employed, solvents such as naphtha, gasoline and other hydrocarbon solvents, which have distillation temperatures in the neighborhood thereof, will efliciently and substantially completely remove the precipitating agent from recovered solids of synthetic resin base coating materials of the class which include alkyd, phenol formaldehyde, urea formaldehyde, Vinylite and resin base surface coating substances.

The washing operation is preferably conducted in a tank and in the presence of a substantially It is found that the recovered mass which, in many cases, is of a liver-like consistency, is readily broken up into relatively small particles by the application of heat (substantially 140 F.) and mechanical agitation during the washing operation, the temperature maintained during the washing may be varied throughout substantial limits depending upon the nature of the composition of the surface coating material being recovered. The resulting finely divided particles of the recovered solid constituent are allowed to settle out and they are thereafter separated from the liquid of the mixture by drawing off the latter or by filtration, if desired. The reconditioned recovered material may then be dissolved in toluol,

xylol or any other suitable solvent and prepared for reuse in a conventional manner. When kerosene or a heavy naphtha is employed as a precipitating agent and thereafter removed from the recovered mass by washing the latter with light naphtha, the resulting recovered material can be readily dissolved in xylol or toluol.

When emulsions of soluble oil and water are used as precipitating agents, the precipitate is preferably freed from both water and soluble oil base by washing it with an alcohol, preferably denatured alcohol. Any of the alcohols may be used in which the recovered material is not excessively soluble.

When recovered surface coating materials are treated with alcohol in this manner and then dissolved in a solvent to condition it for reuse, it is sometimes found that a layer of a solution of alcohol and water is present floating on the top of the reconditioned coating material. This foreign layer can be conveniently removed by centrifuging the mixture in a separator of the type commonly used as milk and cream separators.

In the production of recovered coating materials for many purposes, sludge recovered by precipitation with water and soluble oil may be separated from the main bulk of the precipitating medium and directly dissolved in a suitable coating material solvent and the coating material may then be centrifuged in a separator to remove any remaining soluble oil and water, thus avoiding the alcohol treatment.

It is found that the oil length properties and metallic dryer content of surface coating materials which have been washed with an alcohol are disturbed somewhat by the alcohol wash. This action of the alcohol can readily be compensated for by the addition of metallic dryer and relatively small quantities, say from one to two per cent, of the free fatty acids originally in the resin base of the coating material. Fatty acids may be added in their free state or in the form of fatty acid containing drying oil such as linseed oil, soya bean oil and perilla oil. Other drying oils may also be used for this purpose but it is preferable to use bodied-blown drying oils.

Although but several specific embodiments of the invention are herein shown and described, it will be understood that various changes in the size, shape and arrangement of parts may be made without departing from the spirit of our invention.

What we claim is:

1. The process of recovering the solids of excess sprayed coating material which comprises precipitating said solids by subjecting said excess sprayed coating material to treatment with a water and oil emulsion including mineral oil emulsifiable in water, and separating the resulting precipitate from said emulsion.

2. The process of recovering solids from airborne particles of sprayed coating material including a volatile solvent and non-volatile vehicle having pigment dispersed therein, which comprises precipitating said solids from said solvent and from the air in the form of a sludge having the pigment dispersed in the non-volatile vehicle by treating such air-borne particles with a precipitating agent comprising a water and oil emulsion including mineral oil emulsifiable in water, and separating said precipitating agent from said sludge.

3. The process of recovering the solids of excess sprayed coating material which comprises precipitating said solids by subjecting said excess sprayed coating material to treatment with an alkali free but substantially neutral water and oil emulsion including mineral oil emulsiflable in water, and separating the resulting precipitate from said emulsion.

4. The process of recovering the solids of excess sprayed coating material which comprises precipitating said solids from their solvent by subjecting said excess sprayed coating material to treatment with a water and oil emulsion including mineral oil emulsiflable in water, removing said precipitate from said emulsion, washing the removed precipitate with an excess quantity of an alcohol in which said oil is soluble and in which said precipitate is insoluble, and separating the washed precipitate from the alcohol wash.

5. The process of recovering the solids of excess sprayed coating material which comprises precipitating said solids by subjecting said excess sprayed coating material to treatment with a water and oil emulsion including mineral oil emulsiflable in water, separating said precipitate from said emulsion, and incorporating said separated precipitate in a coating material solvent.

6. The process of recovering and reconditioning the solids of excess resin base sprayed coating material which comprises precipitating said solids from their solvent by subjecting said excess sprayed coating material to treatment with a water and oil emulsion mineral oil emulsiflable in water, mechanically separating said precipitate from said emulsion, washing said separated precipitate with an alcohol in which said oil is solu ble and in which said precipitate is substantially insoluble, compensating for alcohol disturbed oil length properties of said precipitate by adding thereto relatively small quantities of a drying oil fatty acid, and incorporating the resulting product in a surface coating material solvent.

7. The process of recovering and reconditioning the solids of excess resin base sprayed coating material which comprises precipitating said solids by subjecting said excess sprayed coating material to treatment with a water and oil emulsion including mineral oil emulsiflable in water, mechanically separating said precipitate from said emulsion, washing said separated precipitate with an alcohol in which said oil is soluble and in which said precipitate is substantially insoluble, compensating for alcohol disturbed oil length properties of said precipitate by adding thereto relatively small quantities of a bodied blown drying oil, and incorporating the resulting product in a surface coating material solvent.

8. The process of recovering and reconditioning the solids of excess resin base sprayed coating material which comprises precipitating said solids by subjecting said excess sprayed coating material to treatment with a water and oil emulsion including mineral oil emulsiflable in water, mechanically separating said precipitate from said emulsion, washing said separated precipitate with an alcohol in which said oil is soluble and in which said precipitate is substantially insoluble, compensating for alcohol disturbed oil length properties and alcohol soluble metallic dryer loss by adding to said precipitate a drying oil fatty acid and metallic dryer, and incorporating the resulting product in a surface coating material solvent.

9. The process of recovering the solids of excess sprayed coating material which comprises precipitating said solids by subjecting said excess sprayed coating material to treatment with a water and oil emulsion including mineral oil emulsiflable in water, removing said precipitate from the main bulk of said emulsion, dissolving said removed precipitate in a coating material solvent, and centrifuging the resulting solution to separate the latter from remaining quantities of said emulsion.

10. The process of recovering solid constituents of excess sprayed coating material having a vola tile portion including a volatile solvent and having a solid content including a non-volatile vehicle and pigment dispersed therein which comprises precipitating in an enclosure the nonvolatile vehicle and pigment as a sludge with the pigment dispersed therein whereby said sludge is rendered substantially non-adhesive to the surface of the container in which it is maintained by treating air borne particles of such coating material with a precipitating medium comprising a liquid in the presence of which conversion of the recovered product to an insolube or other state not suitable for re-use is substantially prevented and particles of said solid content are precipitated and united together in substantially liver-like mass formation, collecting said precipitating medium and said sludge, said sludge accumulating therein in a mass of liver-like consistency including substantially all the non-volatile ingredients of said excess sprayed coating material in re-usable proportions, and separating said sludge from said precipitating medium and the unvolatilized portion of said solvent remaining in said medium, whereby said sludge is conditioned to be directly redissolved and re-used as a surface coating material in a solvent of the same character as that from which it was precipitated, and redissolving said solid constituent of said sludge in volatile solvent.

11. The process of recovering solid constituents of excess sprayed coating material having a volatile portion including a volatile solvent and having a solid content including a non-volatile vehicle and pigment dispersed therein which comprises precipitating in an enclosure the nonvolatile vehicle and pigment as a sludge with the pigment dispersed therein whereby said sludge is rendered substantially non-adhesive to the surface of the container in which it is maintained by treating air borne particles of such coating material with a precipitating medium comprising a liquid in the presence of which conversion of the recovered product to an insoluble or other state not suitable for reuse is substantially prevented and particles of said solid content are precipitated and united together in substantially liverlike mass formation, collecting said precipitating medium and said sludge, said sludge accumulating therein in a mass of liver-like consistency including substantially all the non-volatile ingredients of said excess sprayed coating material in re-usable proportions, separating said sludge from said precipitating medium and the unvolatilized portion of said solvent remaining in said medium, whereby said sludge is conditioned to be directly redissolved and re-usecl as a surface coating material in a solvent of the same character as that from which it was precipitated, redissolving said solid constituent of said sludge in volatile solvent, and repeatedly recirculating said precipitating medium for re-use.

12. The process of recovering solid constituents of excess sprayed coating material having a volatile portion including a volatile solvent and having a solid content including a non-volatile vehicle and pigment dispersed therein which comprises precipitating in an enclosure the non-volatile vehicle and pigment as a sludge with the pigment dispersed therein whereby said sludge is rendered substantially non-adhesive to the surface of the container in which it is maintained by treating air borne particles of such coating material with a precipitating medium comprising a. liquid in the presence of which conversion of the recovered product to an insoluble or other statenot suitable for re-use is substantially prevented and particles of said. solid content are precipitated and united together in substantially liver-like mass formation, collecting said precipitating medium and said sludge, said sludge accumulating therein in a mass of liver-like consistency including substantially all the non-volatile ingredients of said excess sprayed coating material in re-us'able proportions, removing said sludge from the main bulk of said precipitating medium, whereby said sludge is conditioned to be directly redissolved for re-use as a surface coating material, dissolving said removed sludge in a coating material solvent, and centrifuging the resulting solution to separate from the latter remaining quantities of said emulsion.

13. The process of recovering solid constituents of excess sprayed coating material composed of a solution of said solid constituents and a solvent, which comprises separating from the solvent of suchcoating material substantially all the remaining ingredients thereof as a coherent mass of the particles of said solid constituents by precipitating said remaining ingredients in an enclosure as a sludge whereby said solid constituents are rendered substantially non-adhesive to the surfaces in which they are maintained by treating air borne particles of such coating material with a liquid in the presence of which said solid constituents are insoluble in their solvent and cohere together in surface scum-like formation, collecting said solid constituents in a single layer on said precipitating medium as a surface scum-like substance, said scum-like substance including substantially all the non-volatile ingredients of said excess sprayed coating material in re-usable proportions,- separating said scum-like substance from said precipitating medium whereby said solid constituents thereof are conditioned to be directly redissolved and re-used as a surface coating material in a solvent of the same character as that from which it was precipitated, and forming from said recovered solid constituents a coating material of the same character as that from which they were recovered by dissolving said solid constituents of said scum in said coating material solvent.

SEYMOUR G. SAUNDERS. HARRY MORRISON.

1.PublishNumber: US-2086514-A

2.Date Publish: 19370706

3.Inventor: SAUNDERS SEYMOUR G.

MORRISON HARRY

4.Inventor Harmonized: SAUNDERS SEYMOUR G()

HARRY MORRISON()

5.Country: US

6.Claims:

7.Description:

(en)July 6, 193 7.

S. G. SAUNDERS Er AL COATING MATERIAL RECOVERY PROCESS Filed July 14, 1936 2 Sheets-Sheet l 3 f QSEYM OUR a. SAUNBEHE AND HARRY MORRlON.

GttornegS y 1937- s. G. SAUNDERS ET AL 2,086,514

COATING MATERIAL: RECOVERY PROCESS Filed July 14, 1936 2 Sheets-Sheet 2 lhwemor \SEYM OUR G. 6A UNDERS AND HARRY MORRIQSON.

Gttornegs as to return them to a condition suitable for reprovide an improved method of this character Patented July 6, 1937 COATING MATERIAL RECOVERY PROCESS Seymour G. Saunders, Birmingham, and Harry Morrison, Detroit, Mich, assignors to Chrysler Corporation, Highland Park, Mich, a. corporation of Delaware Application July Serial No. 90,559

a precipitating agent of this character in the presence of excess quantities of which the solids or non-volatile constituents of the surface coating material are insoluble in the solvent of the latter and in which such solvent is either soluble or mixable.

Still further objects of the invention are to provide in the force. draft air passage of a spray booth, curtains of liquid material for washing out the solid constituents of the air passing from the booth; and to provide curtains of liquid material which serve as precipitating agent for the particular type of solids of the coating material being sprayed in the booth.

Another object of the invention is to provide a coating material recovery and reconditioning process and apparatus by which the recovered products can be used in compounding materials of the same or different character from which they were derived or in manufacturing articles of diverse compositions.

Additional objects of the invention are to provide an improved exhaust system for spray coating booths which is particularly adapted to facilitate the removal of solid coating material constituents from the air exhausted therefrom; to provide means in the exhaust system of a spray chamber for reversing the course of the flow of the air passing therefrom and substantially simultaneously subjecting the air to a spray while its course of travel is being reversed; to provide an outlet for the spray liquid and solid material collected thereby which is spaced from the normal path of the main portion of the air being exhausted from the spray boating chamber; and to provide a sump for collecting the sprayed washing liquids and solid matter collected thereby.

Another object of the invention is to provide a plurality of separate sumps for receiving liquid washing mediums carrying respectively differentlycolored coating material constituents; to provide a plurality of outlets for the washing medium, each of which is adapted to communicate with one of the sumps respectively; and to provide selectively controllable means which are adapted to be so positioned as to direct the differently colored solid coating material constituents to their respective sumps.

In general, the ingredients of surface coating materials can be broadly classified as volatile and non-volatile solvents, non-volatile vehicle, pigment and coloring matter, and driers. In the manufacture of such coating materials a large part of the time, labor and machinery cost in- 13 Claims.

This invention relates to an improved method and apparatus for recovering the non-volatile ingredients of sprayed surface coating materials, commonly called solids, from the atmosphere of the space in which they are applied, and is a continuation in part of our applications, Serial No. 19,794, filed May 4, 1935, and Serial No. 45,962, filed October 21, 1935.

More particularly, the invention pertains to the recovery of solids of paint, lacquer, natural enamel, synthetic enamels and the like.

The term solids, as used herein and as conventionally employed in the surface coating art refers to those portions of surface coating material which remain, either in their initial or chemically altered form, in a normally set deposit of such coating materials, including the non-volatile vehicle and pigment.

One of the main objects of the invention is to by which the recovered products are retained in such condition that they can be readily dissolved in, or dissociated throughout a solvent with which they had previously been associated, so

use in an identical manner.

Another object of the invention is to provide a recovery method of this character by which substantially all the solids of the coating material of the air withdrawn from the vicinity of the application of coating materials is precipitated and collected.

Another object of the invention is to provide a suitable precipitating agent for the particular solids of the coating material to be recovered, which both separates the coating material from the air and precipitates the solids thereof from their solvent, while leaving the pigment of the coating material thoroughly dispersed throughout the vehicle thereof, and in condition to be re-incorporated in a solvent without requiring regrinding.

Another object of the invention is to provide precipitating agents of this character which lubricate the recovered material or the surfaces with which the recovered material contacts or which otherwise render the recovered material non-adhesive to such surfaces.

A further object of the invention is to provide an improved method and apparatus for recovering the solids of sprayed coating materials which prevents oxidation thereof and conversion of the recovered product to an insoluble, or other state not suited for re-use in coating operations.

Another object of the invention is to provide volves the grinding of the pigment into a finely divided and dispersed state in the non-volatile vehicle. Any recovery process during which this dispersion of pigment and npn-volatile vehicle is destroyed, naturally falls far short of saving these cost factors. In the present process the nonvolatile vehicle is recovered with the pigment dispersed therein substantially as thoroughly as it was in the initial surface coating material. Briefly, this is accomplished by precipitating the solids in the form of a sludge with the pigment thoroughly dispersed in the vehicle by treating excess sprayed coating material with a liquid, in

the presence of excess quantities of which the solids are insoluble and immiscible in the solvent.

An illustrative embodiment of the invention is shown in the accompanying drawings, in which:

Fig. 1 is an end elevational view of a spraying booth equipped with solid coating material constituent recovering apparatus embodying the invention.

Fig. 2 is a horizontal sectional view taken on the line 2-2 of Fig. 1.

Fig. 3 is a vertical sectional view taken on the line 3-3 of Fig. 2.

Fig. 4 is a fragmentary sectional view taken on the lined-4 of Fig. 3.

Fig. 5 is a fragmentary illustrative horizontal sectional view taken on the line 5-5 of Fig. 3 and in addition showing a precipitating agent recirculating system.

In the drawings is shown one form of spray chamber, generally designated by the numeral Ill, with which the solid matter recovery apparatus may be used. The spraying chamber includes a casing having end walls ll provided with registering openings l2 for accommodating the passage of articles l3 through the interior thereof. The articles are preferably conveyed through the spray chamber III by a conveyor which includes a rail l4 extending longitudinally of the chamber l0 and located at the upper extremities of the openings l2 thereof. The rail I4 is adapted to movably support a plurality of carriers l5 which are preferably attached to a continuous conveyor chain (not shown). The spray chamber III has a roof H5 in which is formed an air inlet opening 11 that communicates with a conduit i8 leading from an external or internal source of air. Disposed immediately below the air inlet I1 is an inverted frusto-conical deflector [9 having vanes 20 so constructed and arranged as to distribute the air current entering the inlet ll throughout substantially all portions of the interior of the chamber l0. Provided at the lower longitudinal extremity of the spray chamber Ill on the side thereof opposite from the location at which the coating material is discharged upon the articles by a spray gun 2|, or other suitable means, is an inclined baifie 22 which slopes downwardly and inwardly toward the central portion of the floor 23 of the chamber. An air outlet opening 24 is provided in the floor 23 adjacent the lower extremity of the bailie 22 for permitting the escape of the air admitted through the inlet 21. A grill 25 is disposed. in the outl t opening 24 for the purpose of preventing the passage of articles or spray gun parts or other devices which may accidentally be dropped in the spraying chamber.

The air current is drawn through the inlet opening I! and through the interior of the spraying chamber H] by a blower 26 located externally of the spraying chamber and having a discharge conduit 21 which preferably leads to the atmosphere. The blower 26 includes an inlet conduit 21' which communicates with an air passage 28 disposed below the spraying chamber l0 and extending longitudinally thereof. The passage 28 leads from the outlet at of the spraying chamber In and is provided at its inlet end with curvilinear bafiles 29 and 30 which direct the air passing through the outlet 28 rightwardly as viewed in Fig. 3 toward the right extremity of the passage 23; The lowermost baflle 29 extends rightwardly further than the baflle 30 but it terminates in spaced relation to the right extremity of the passage 28 so as to permit the air current to be reversed in direction of flow by a curvilinear bafile 3! located at the upper right extremity of the air passage, as viewed in Fig. 3. The air current flows around the right extremity of the lowermost baflle 29 and then continues in a leftward course toward the blower 26. An eliminator 32 is provided adjacent the outlet of the air passage 28 for removing any liquid such as spray coating material, or the precipitating agent introduced into the air current in the manner hereinafter set forth, before the air enters the blower 26 and discharge pipe 21.

The spray chamber l0 and the air passage 28 are provided with means for subjecting the air current circulated through the system to the action of an agent for precipitating the solids oi the excess sprayed coating material which is carried by the air current. The precipitating agent I preferably comprises liquid which not only washes or otherwise removes the sprayed coating material from the air current but which also precipitates the solid constituent thereof from the solvent in which they are incorporated.

In the form of the invention illustrated, a discharge pipe 33 having a plurality of relatively small outlet orifices or other spray forming means, extends longitudinally of the spray chamber I 0 and is located adjacent the back wall 34 thereof as illustrated in Fig. 3. The orifices, or spray devices of the discharge pipe 33 are so constructed and arranged as to direct the precipitating agent upon the internal surface of the rear wall 34 and to cause the liquid to flow downwardly thereon substantially in the form of a sheet or curtain. The liquid precipitating agent is then directed inwardly toward the outlet opening 24 by the inclined baflie 22 and ultimately flows through the outlet openings 24 along with the air current. That portion of the excess sprayed coating material which impinges upon the sheet or curtain of liquid precipitating agent discharged by the pipe 33 is removed from the air current and the solids thereof are precipitated from their solvent. Any portion of the air ladened with spray coating material which is not subjected to the washing and precipitated action of the agent discharged by the pipe 33 is thoroughly treated with precipitating agent by a pair of spray devices 35 and 36 located in the left end portion of the air passage 28. The uppermost spray device 35 includes a plurality of outlet orifices or spray nozzles which discharge the precipitating agent in the direction of travel of the air current. flowing through the section of the passage 28 above the baille 29, and the spray device 26 likewise includes a plurality of orifices or discharge nozzies which spray precipitating agent in a direction opposite to the direction of flow of the air current through that portion of the air passage 26 located below the baiile 29. In this manner the precipitating agent is applied to the air current of the passage 28 at the location therein where the air current is reversed in the direction of movement.

Provided in the lower wall of the air passage 28 is an outlet 31 for accommodating the flow of the precipitating agent and solids of the spray coating material therefrom. The outlet 31 communicates with an elongated passageway or conduit 38 having a plurality of longitudinally adjacent discharge outlets 39, each of which communicates with a separate sump 40, as illustrated in Fig. 5. In the illustration shown there are provided three outlet openings 39 and associated sumps 40, each of which is intended to receive precipitating agent ladened with a differently colored solid coating material constituent. Although only three sumps are illustrated in the drawings, there may be provided as many thereof asarerequired to separate and segregate the,

solids of differently colored coating materials that are applied in the spray chamber l0.

Each outlet 39 of the conduit 38 is provided with a valve member or other adjustable closure,

illustrated in the drawings as a hinged damper 4|. Each closure 4! is provided with control mechanism, illustrated in Fig. 3, which includes a ball crank lever 42 pivotally mounted on the back wall 43 of the air passage 28 and having a lower arm 44 pivotally connected with the closure 4| by a link 45. The bell crank lever 42 also includes an upper arm 46 which is operatively connected with a control rod 41 extending transversely of the spray booth and having an operating handle 4I' located within convenient reach of the operator and preferably disposed on that side of the spray booth at which the operator stands. The closures 4| may be selectively controlled by the operator to correspond with the particular color of surface coating material being applied in the spray chamber In so as to deliver substantially all of the precipitating agent carrying any colored surface coating material to its proper sump. When it is not desired to separate the differently colored coating materials, they may all be collected in one sump and the resulting recovered product may be used in conjunction with predominating pigments, such as black, or for protective purposes where appearance is immaterial.

The recovered solids from many sprayed surface coating materials will sink to the bottom of the sump in the form of a sludge when a proper precipitating agent is employed and in this case the solids may be conveniently removed from the sump 40 by the aid of a liquid pervious screen 48 which is preferably disposed at the bottom of each sump 40. Cables 49 are attached to the screen 48 and preferably extended over a pulley 53 so as to enable convenient vertical movement of the screen 48- from the interior of its sump when it is desired to displace the precipitated solids therefrom.

With the use of certain precipitating agents for removing the solids of some sprayed surface coating materials, it is found that the solids float on the top of the liquid, in the form of a scum or sludge, in the sump 40 and may be conveniently removed therefrom by scraping the floating scum-like substance so formed into a trough from which it may be conveniently removed for further operation in accordance with the recovery process.

The precipitated solids obtained in either of the foregoing ways include the non-volatile vehicle dispersed coloring matter or pigment and substantially all other ingredients which comprise the solids of surface coating materials. In this recovery product, the pigment is thoroughly dispersed in the non-volatile vehicle in substantially that condition produced by the original grinding operations employed' in the initial manufacture of the coating material. These recovered products are then separated from the precipitating agent, preferably by initially removing the main portion of the latter in a press and then allowing the material to dry. For some purposes more complete removal of the precipitating agent is desirable and in this event the precipitating agent is preferably washed out or extracted, as hereinafter more clearly set forth, with a suitable solvent therefor which will not dissolve or otherwise seriously disturb the condition of the recovered solids. The thus reconditioned recovered material may then be dissolved in a solvent of the same character as that from which it had previously been separated in order to produce surface coating material which is otherwise wasted.

Various precipitating agents may be used in the foregoing process depending mainly upon the particular nature of the coating material from which the solids are to be recovered. In recovering the solids from cellulose lacquers it is preferable to use water as a precipitating agent, while in recovering the solids from paint and enamels of the synthetic and natural type, the use of a mineral oil as the precipitating agent is particularly advantageous. While a vast number of mineral oils of different distillation temperatures may be employed for this purpose, it is preferable to use those which do not readily evaporate such as mineral oils having a distillation temperature not lower than that of kerosene. Paraifin oil and mineral oils having distillation temperatures be- I tween those of paraffin oil, and kerosene operate successfully in recovering solids from sprayed paint, lacquer and enamels as well as from glyptol resin base synthetic coating materials.

The solids of substantially all spraying types of coating materials .can be economically and commercially recovered by using in the foregoing process a precipitating agent comprising an emulsion of soluble oil in water. This precipitating liquid is particularly suitable for the recovery of natural resin and oil base coating materials and synthetic resin base coating materials such as alkyd, resin base varnishes, enamels and lacquers, and the like. It may be used in the recovery of nitrocellulose lacquers, but, for the purpose of economy, water is recommended for recovering this type of coating material. The oil content effectively prevents the deposited precipitate from adhering to the surfaces of the enclosure in which the process is conducted and through which such materials are conveyed.

Water miscible oils, commonly called soluble oils, of variouscharacters may be used in our improved recovery process. These oils are readily miscible with water and maintain a stable emulsion. When a soluble oil base derived by treatment of mineral oil, for example, with naphthenic acid is used, it is preferable to neutralize the free acid content with a suitable alkali such as potassium hydroxide or sodium hydroxide. Any soluble oil base employed should be either neutral or only slightly acid for the presence of a comparatively strong alkaline condition results in saponification, and hence waste of the resin content of the solids. Other alkali may be used, but the introduction with the alkali of solvents for the resins of the solids should be carefully guarded against.

Although proportions of soluble 011 base and large excess of washing solvent.

water of the precipitating medium may vary within wide limits, for purposes of economy, flowability and general convenience of operation, emulsions of water and oil, respectively, varying from parts of water to 1 part of soluble oil base; to 30 parts of water to one part of soluble oil base are preferred.

Irrespectiveof the saving resulting from the recovery of excess sprayed coating materials, the use of precipitating agents in the foregoing manner and in which the solids of the coating materialare not soluble or rendered gummy, is of substantial value. The elimination of the nuisance problems involved in the discharging of air fromspray booths into the atmosphere in densely inhabited regions, as well as the saving in cleaning of the apparatus and removing therefrom, deposited solid and semi-solid accumulations represent a material saving in spray booth operation even though no attempt is made to reuse the recovered coating materials.

The precipitating medium may be withdrawn periodically from the sump 40 through conduits 52, each having a valve 53 therein, and discharged into a receptacle 54. The receptacle 54 is preferably provided with a filtering partition 55 through which the liquid precipitating agent must pass before being returned to the pipe 33 and spray devices 35 and 36 through an outlet pipe 56 having a branch pipe 51 communicating with the discharge pipe 33, and a branch pipe 58 communicating with the spray devices 35 and 35. The branch pipes 51 and 58 are preferably provided with valves 59 and 60, respectively, for individually controlling the flow of precipitating liquids to the pipe 33 and spray devices 35 and 36, respectively. The precipitating liquid may be recirculated in the foregoing manner and repeatedly redischarged in the spraying cham-' her It) under the pressure of a pump 6| included in the outlet conduit 56 or otherwise suitably located.

Complete removal of any precipitating agent which remains in the recovered product can be accomplished by washing the material with a suitable solvent for the particular precipitating agent used in the recovery process and in which the solids are insoluble. When mineral oil is employed, solvents such as naphtha, gasoline and other hydrocarbon solvents, which have distillation temperatures in the neighborhood thereof, will efliciently and substantially completely remove the precipitating agent from recovered solids of synthetic resin base coating materials of the class which include alkyd, phenol formaldehyde, urea formaldehyde, Vinylite and resin base surface coating substances.

The washing operation is preferably conducted in a tank and in the presence of a substantially It is found that the recovered mass which, in many cases, is of a liver-like consistency, is readily broken up into relatively small particles by the application of heat (substantially 140 F.) and mechanical agitation during the washing operation, the temperature maintained during the washing may be varied throughout substantial limits depending upon the nature of the composition of the surface coating material being recovered. The resulting finely divided particles of the recovered solid constituent are allowed to settle out and they are thereafter separated from the liquid of the mixture by drawing off the latter or by filtration, if desired. The reconditioned recovered material may then be dissolved in toluol,

xylol or any other suitable solvent and prepared for reuse in a conventional manner. When kerosene or a heavy naphtha is employed as a precipitating agent and thereafter removed from the recovered mass by washing the latter with light naphtha, the resulting recovered material can be readily dissolved in xylol or toluol.

When emulsions of soluble oil and water are used as precipitating agents, the precipitate is preferably freed from both water and soluble oil base by washing it with an alcohol, preferably denatured alcohol. Any of the alcohols may be used in which the recovered material is not excessively soluble.

When recovered surface coating materials are treated with alcohol in this manner and then dissolved in a solvent to condition it for reuse, it is sometimes found that a layer of a solution of alcohol and water is present floating on the top of the reconditioned coating material. This foreign layer can be conveniently removed by centrifuging the mixture in a separator of the type commonly used as milk and cream separators.

In the production of recovered coating materials for many purposes, sludge recovered by precipitation with water and soluble oil may be separated from the main bulk of the precipitating medium and directly dissolved in a suitable coating material solvent and the coating material may then be centrifuged in a separator to remove any remaining soluble oil and water, thus avoiding the alcohol treatment.

It is found that the oil length properties and metallic dryer content of surface coating materials which have been washed with an alcohol are disturbed somewhat by the alcohol wash. This action of the alcohol can readily be compensated for by the addition of metallic dryer and relatively small quantities, say from one to two per cent, of the free fatty acids originally in the resin base of the coating material. Fatty acids may be added in their free state or in the form of fatty acid containing drying oil such as linseed oil, soya bean oil and perilla oil. Other drying oils may also be used for this purpose but it is preferable to use bodied-blown drying oils.

Although but several specific embodiments of the invention are herein shown and described, it will be understood that various changes in the size, shape and arrangement of parts may be made without departing from the spirit of our invention.

What we claim is:

1. The process of recovering the solids of excess sprayed coating material which comprises precipitating said solids by subjecting said excess sprayed coating material to treatment with a water and oil emulsion including mineral oil emulsifiable in water, and separating the resulting precipitate from said emulsion.

2. The process of recovering solids from airborne particles of sprayed coating material including a volatile solvent and non-volatile vehicle having pigment dispersed therein, which comprises precipitating said solids from said solvent and from the air in the form of a sludge having the pigment dispersed in the non-volatile vehicle by treating such air-borne particles with a precipitating agent comprising a water and oil emulsion including mineral oil emulsifiable in water, and separating said precipitating agent from said sludge.

3. The process of recovering the solids of excess sprayed coating material which comprises precipitating said solids by subjecting said excess sprayed coating material to treatment with an alkali free but substantially neutral water and oil emulsion including mineral oil emulsiflable in water, and separating the resulting precipitate from said emulsion.

4. The process of recovering the solids of excess sprayed coating material which comprises precipitating said solids from their solvent by subjecting said excess sprayed coating material to treatment with a water and oil emulsion including mineral oil emulsiflable in water, removing said precipitate from said emulsion, washing the removed precipitate with an excess quantity of an alcohol in which said oil is soluble and in which said precipitate is insoluble, and separating the washed precipitate from the alcohol wash.

5. The process of recovering the solids of excess sprayed coating material which comprises precipitating said solids by subjecting said excess sprayed coating material to treatment with a water and oil emulsion including mineral oil emulsiflable in water, separating said precipitate from said emulsion, and incorporating said separated precipitate in a coating material solvent.

6. The process of recovering and reconditioning the solids of excess resin base sprayed coating material which comprises precipitating said solids from their solvent by subjecting said excess sprayed coating material to treatment with a water and oil emulsion mineral oil emulsiflable in water, mechanically separating said precipitate from said emulsion, washing said separated precipitate with an alcohol in which said oil is solu ble and in which said precipitate is substantially insoluble, compensating for alcohol disturbed oil length properties of said precipitate by adding thereto relatively small quantities of a drying oil fatty acid, and incorporating the resulting product in a surface coating material solvent.

7. The process of recovering and reconditioning the solids of excess resin base sprayed coating material which comprises precipitating said solids by subjecting said excess sprayed coating material to treatment with a water and oil emulsion including mineral oil emulsiflable in water, mechanically separating said precipitate from said emulsion, washing said separated precipitate with an alcohol in which said oil is soluble and in which said precipitate is substantially insoluble, compensating for alcohol disturbed oil length properties of said precipitate by adding thereto relatively small quantities of a bodied blown drying oil, and incorporating the resulting product in a surface coating material solvent.

8. The process of recovering and reconditioning the solids of excess resin base sprayed coating material which comprises precipitating said solids by subjecting said excess sprayed coating material to treatment with a water and oil emulsion including mineral oil emulsiflable in water, mechanically separating said precipitate from said emulsion, washing said separated precipitate with an alcohol in which said oil is soluble and in which said precipitate is substantially insoluble, compensating for alcohol disturbed oil length properties and alcohol soluble metallic dryer loss by adding to said precipitate a drying oil fatty acid and metallic dryer, and incorporating the resulting product in a surface coating material solvent.

9. The process of recovering the solids of excess sprayed coating material which comprises precipitating said solids by subjecting said excess sprayed coating material to treatment with a water and oil emulsion including mineral oil emulsiflable in water, removing said precipitate from the main bulk of said emulsion, dissolving said removed precipitate in a coating material solvent, and centrifuging the resulting solution to separate the latter from remaining quantities of said emulsion.

10. The process of recovering solid constituents of excess sprayed coating material having a vola tile portion including a volatile solvent and having a solid content including a non-volatile vehicle and pigment dispersed therein which comprises precipitating in an enclosure the nonvolatile vehicle and pigment as a sludge with the pigment dispersed therein whereby said sludge is rendered substantially non-adhesive to the surface of the container in which it is maintained by treating air borne particles of such coating material with a precipitating medium comprising a liquid in the presence of which conversion of the recovered product to an insolube or other state not suitable for re-use is substantially prevented and particles of said solid content are precipitated and united together in substantially liver-like mass formation, collecting said precipitating medium and said sludge, said sludge accumulating therein in a mass of liver-like consistency including substantially all the non-volatile ingredients of said excess sprayed coating material in re-usable proportions, and separating said sludge from said precipitating medium and the unvolatilized portion of said solvent remaining in said medium, whereby said sludge is conditioned to be directly redissolved and re-used as a surface coating material in a solvent of the same character as that from which it was precipitated, and redissolving said solid constituent of said sludge in volatile solvent.

11. The process of recovering solid constituents of excess sprayed coating material having a volatile portion including a volatile solvent and having a solid content including a non-volatile vehicle and pigment dispersed therein which comprises precipitating in an enclosure the nonvolatile vehicle and pigment as a sludge with the pigment dispersed therein whereby said sludge is rendered substantially non-adhesive to the surface of the container in which it is maintained by treating air borne particles of such coating material with a precipitating medium comprising a liquid in the presence of which conversion of the recovered product to an insoluble or other state not suitable for reuse is substantially prevented and particles of said solid content are precipitated and united together in substantially liverlike mass formation, collecting said precipitating medium and said sludge, said sludge accumulating therein in a mass of liver-like consistency including substantially all the non-volatile ingredients of said excess sprayed coating material in re-usable proportions, separating said sludge from said precipitating medium and the unvolatilized portion of said solvent remaining in said medium, whereby said sludge is conditioned to be directly redissolved and re-usecl as a surface coating material in a solvent of the same character as that from which it was precipitated, redissolving said solid constituent of said sludge in volatile solvent, and repeatedly recirculating said precipitating medium for re-use.

12. The process of recovering solid constituents of excess sprayed coating material having a volatile portion including a volatile solvent and having a solid content including a non-volatile vehicle and pigment dispersed therein which comprises precipitating in an enclosure the non-volatile vehicle and pigment as a sludge with the pigment dispersed therein whereby said sludge is rendered substantially non-adhesive to the surface of the container in which it is maintained by treating air borne particles of such coating material with a precipitating medium comprising a. liquid in the presence of which conversion of the recovered product to an insoluble or other statenot suitable for re-use is substantially prevented and particles of said. solid content are precipitated and united together in substantially liver-like mass formation, collecting said precipitating medium and said sludge, said sludge accumulating therein in a mass of liver-like consistency including substantially all the non-volatile ingredients of said excess sprayed coating material in re-us'able proportions, removing said sludge from the main bulk of said precipitating medium, whereby said sludge is conditioned to be directly redissolved for re-use as a surface coating material, dissolving said removed sludge in a coating material solvent, and centrifuging the resulting solution to separate from the latter remaining quantities of said emulsion.

13. The process of recovering solid constituents of excess sprayed coating material composed of a solution of said solid constituents and a solvent, which comprises separating from the solvent of suchcoating material substantially all the remaining ingredients thereof as a coherent mass of the particles of said solid constituents by precipitating said remaining ingredients in an enclosure as a sludge whereby said solid constituents are rendered substantially non-adhesive to the surfaces in which they are maintained by treating air borne particles of such coating material with a liquid in the presence of which said solid constituents are insoluble in their solvent and cohere together in surface scum-like formation, collecting said solid constituents in a single layer on said precipitating medium as a surface scum-like substance, said scum-like substance including substantially all the non-volatile ingredients of said excess sprayed coating material in re-usable proportions,- separating said scum-like substance from said precipitating medium whereby said solid constituents thereof are conditioned to be directly redissolved and re-used as a surface coating material in a solvent of the same character as that from which it was precipitated, and forming from said recovered solid constituents a coating material of the same character as that from which they were recovered by dissolving said solid constituents of said scum in said coating material solvent.

SEYMOUR G. SAUNDERS. HARRY MORRISON.

You are contracting for Coating material recovery process

Expert Coating material recovery process

Select an intermediary organization for the product Coating material recovery process

English

English Tiếng Việt

Tiếng Việt

You are commenting for Coating material recovery process